During the refinish process, it was easy to see some trends when it came to San Jose fasteners. The most predominant body fastener is the star HTS bolt. There are probably 50+ of those that were refinished. Next most common would be the double ticks. Finally, the next one would be the HTS star with concentric circles. For the small sheet metal screws, like that attach the splash shields, they were all the diamond marking. Most everything else was pretty consistent with other assembly plants. Refinishing these fasteners will yield an extremely accurate representation of what was used at San Jose around Feb. '65. There will be no reproduction fasteners on this car.

Here are a few of the odd-ball bolts. The first one is the RBW. There was only one of these in the mix. I actually don't know where it came from or which car. There was a slight bit of pitting on this bolt, so not sure I would use it on the K.

Next are a couple of other one-off bolts. There were just a handful of disc washer bolts used at this time in San Jose.

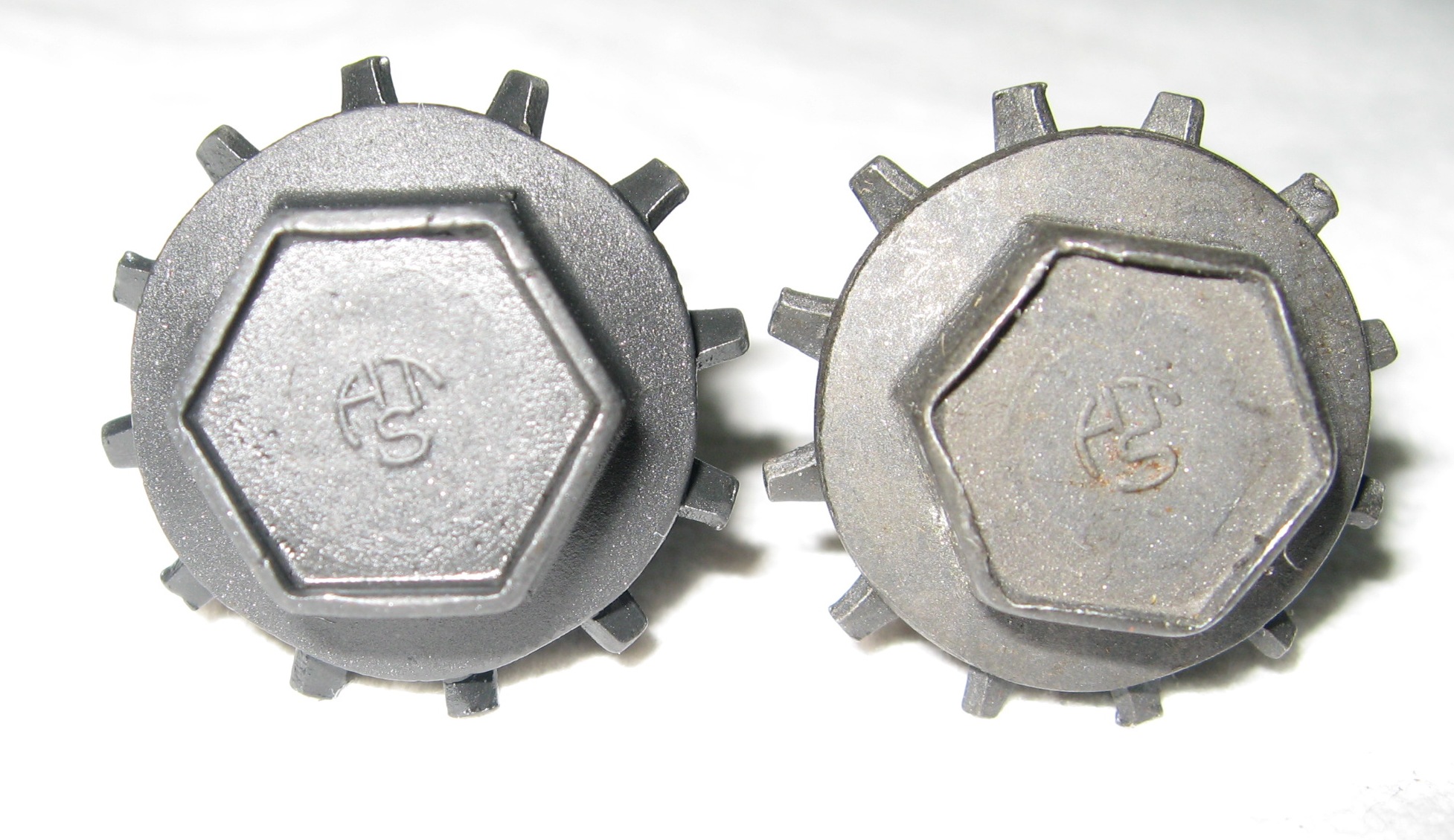

Now to something a little more interesting. Ever wondered how accurate the AMK bolts are? Here's one side by side with an original. The one on the left is a refinished original, one on the right is an AMK one. Of course, I have not made a large study of HTS star bolts to determine if there were variations in the logo. But, if you look closely, you can see there is a subtle difference in the 'S'.

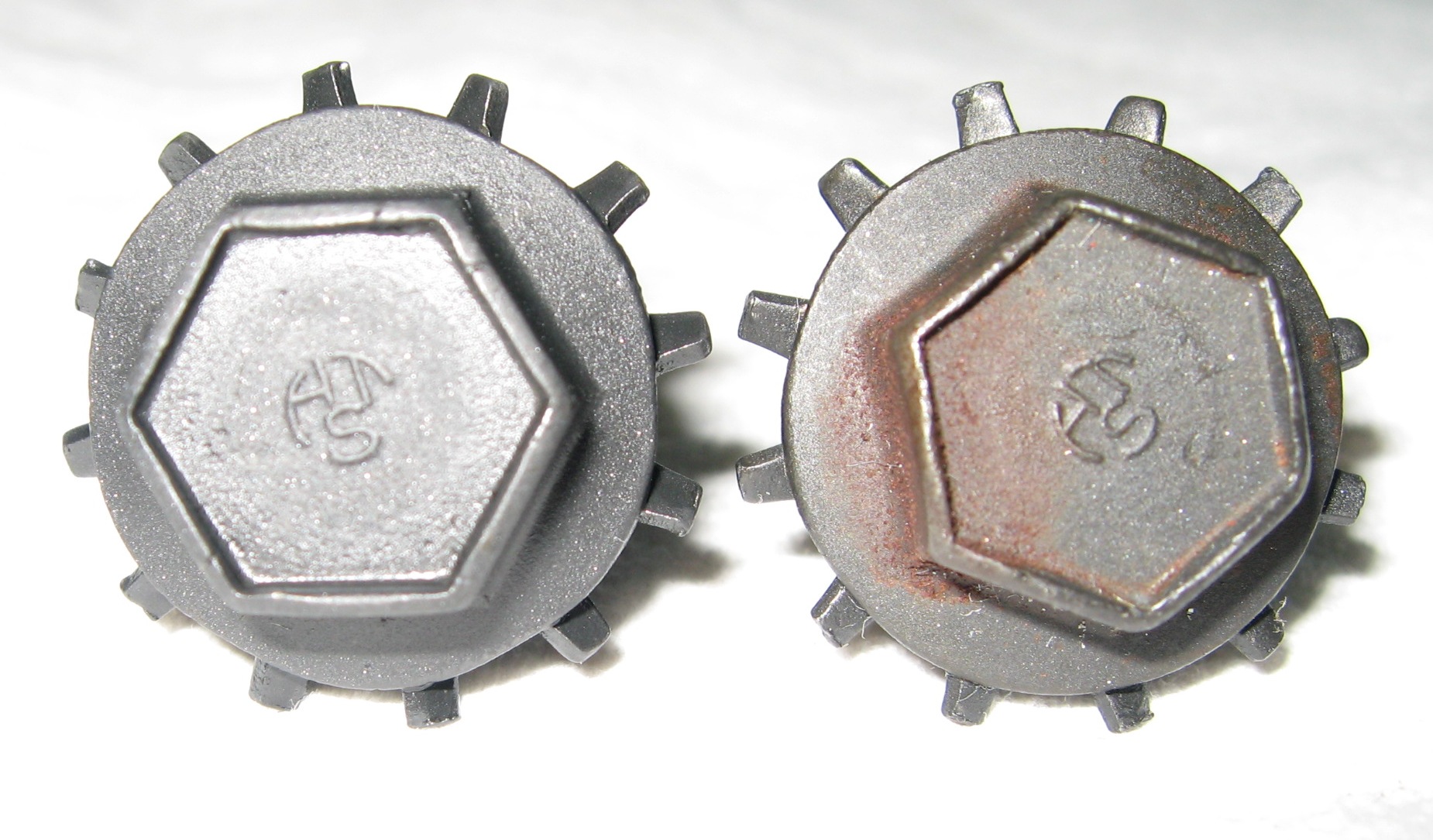

Here's an original refinished bolt on the left compared to an excellent original on the right. The phosphate match is pretty much dead-on.

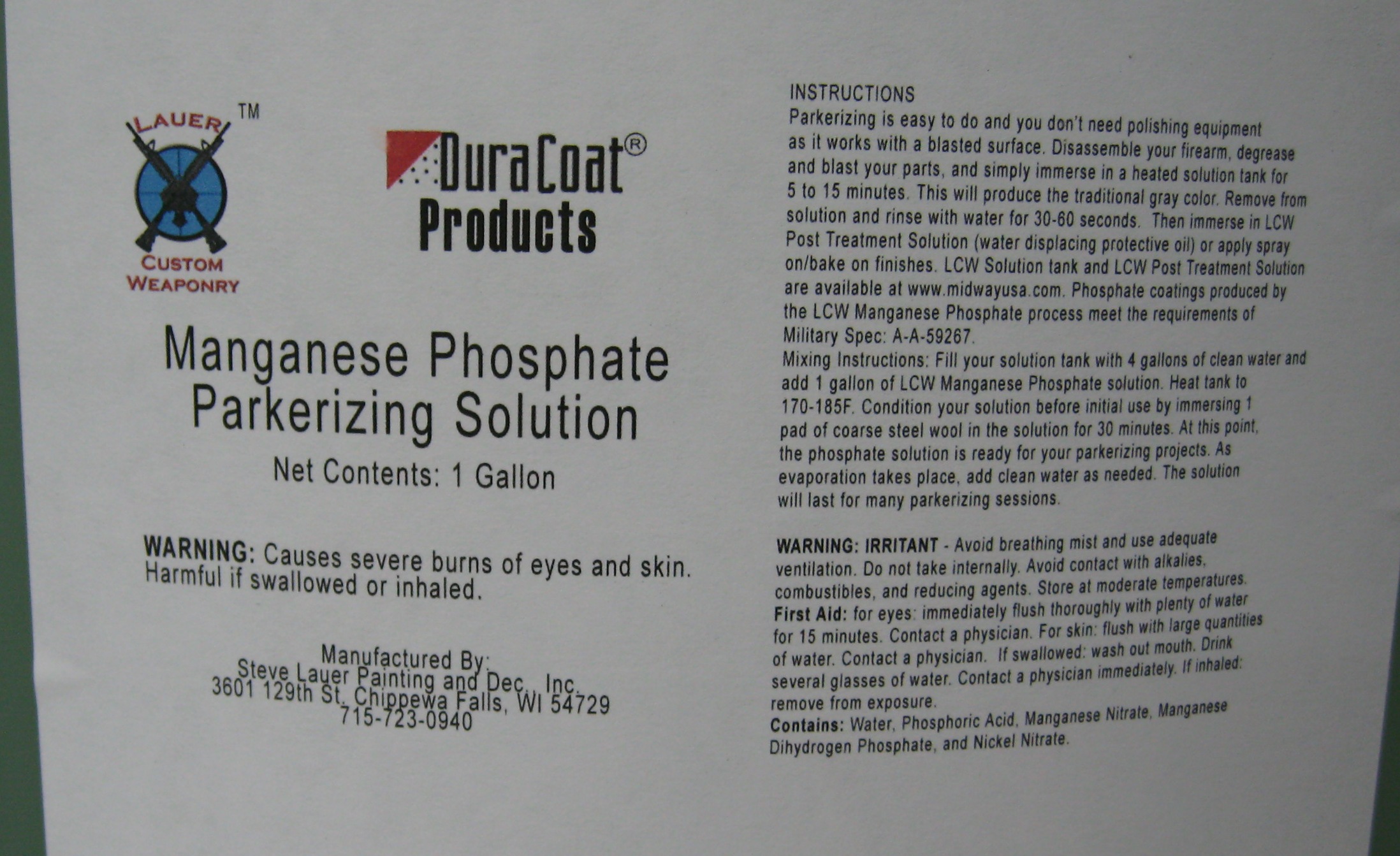

For those interested, here is the label of the solution I used:

Will be going to CA this week to the MCA National show. Hope to start doing some serious assembly work when I get back!

Hi,

ReplyDeleteThanks for the phosphating solution tip, I may give it a try. What type of oil are you dipping the parts in?

I use regular 30 weight engine oil. I soak the parts for 24 hours.

ReplyDelete