Snapped a few pics of misc parts. First is of a couple original pitman arms. The original from the K code and the one from the red V8 coupe. They are both in really nice condition. Paint marks were on one of them, appeared to be light blue and probably brown.

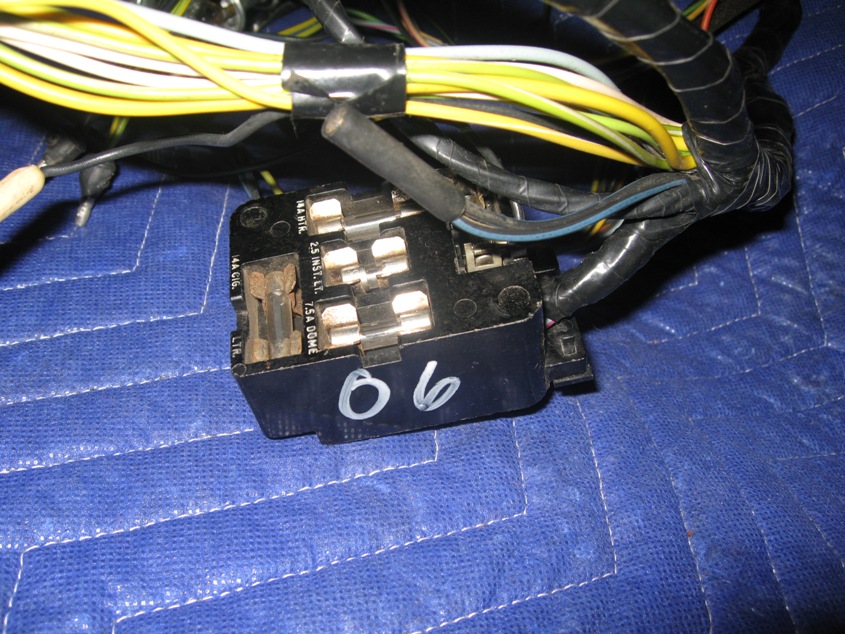

Next is the typical yellow paint daubs on the strut rods. The yellow daub let the assembly line worker know which way to install the strut rod. If you hold an original one out, they are not perfectly straight. The end that attaches to the control arm curves up. The yellow daub matches the side with the narrow raised "slit", which should be pointing down when installed. Have seen the yellow mark on other original strut rods, so this seemed to be something rather consistent. The Ford assembly manual actually makes note of the mark and what it means also.

Next up is an original lower control arm. As can be seen, these were date stamped with month/year. The month letter is hard to make out on this LCA, possibly a G4. Second pic shows the original style ball joint boot.

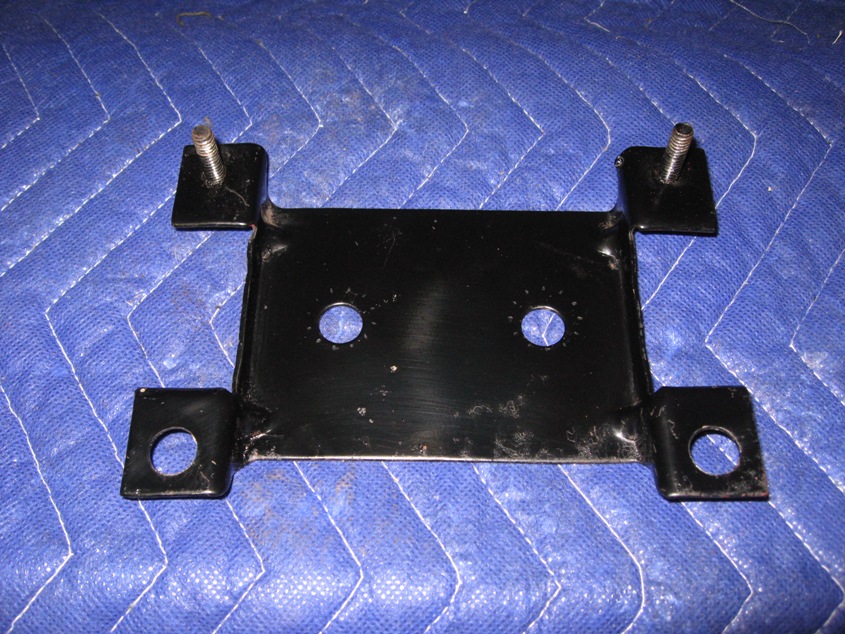

Last pic is an original hi-po air cleaner base. There are still a lot of unknowns when it comes to these. Mostly concerning date stamps and paint color. This one is from a January '65 build car and is most definitely the original. There is no date stamp on it and the original paint color is gold.